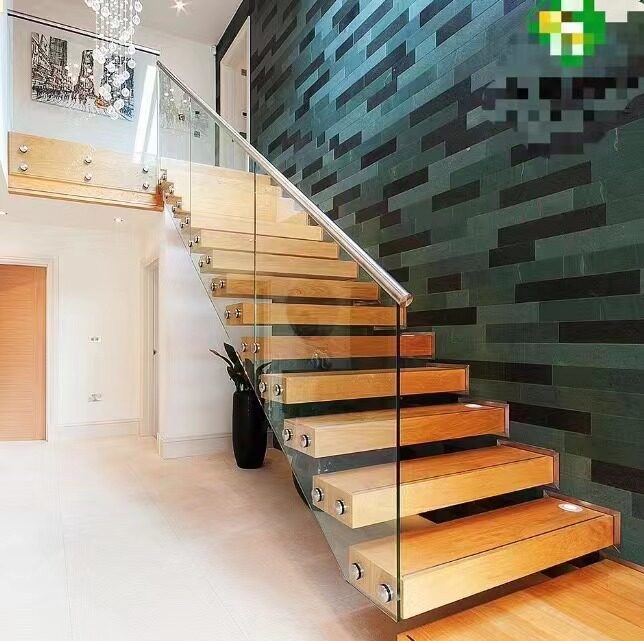

ASSEMBLING: Precision and Sturdiness in Stainless Steel Railing Systems

Assembling is a pivotal step in the stainless steel railing production process, where individual components come together to form a seamless and sturdy structure. At RUNTIAN, we understand the significance of this process in creating railing systems that embody both precision and durability. With over 15 years of expertise in the industry, our commitment to excellence has made us a trusted expert in railing systems and accessories. In this article, we delve into the art of assembling and how it transforms stainless steel components into elegant and resilient railing systems.

The Essence of Assembling:

Assembling is the culmination of the creative process, where stainless steel components take their rightful place in the railing system's design. Each component plays a vital role in the overall structure, and assembling ensures that they fit together seamlessly to create a unified and functional whole.

Skilled Craftsmanship:

At RUNTIAN, we take pride in the skilled craftsmanship that goes into the assembling process. Our experienced technicians possess the expertise and attention to detail required to ensure precision in every joint and connection. Their meticulous work guarantees that the railing system stands firm and exudes elegance in every aspect.

Precision Engineering:

The art of assembling demands precision engineering, where each component must align flawlessly with its counterparts. At RUNTIAN, we employ advanced techniques and tools to achieve this level of accuracy. The result is a railing system that boasts a seamless and aesthetically pleasing appearance.

Structural Integrity:

The strength and sturdiness of the railing system depend on the integrity of its assembling. At RUNTIAN, we prioritize the structural integrity of every railing system we create. Our rigorous quality control ensures that each connection is secure and capable of withstanding the test of time.

Meeting Safety Standards:

Assembling is not only about aesthetics but also about ensuring the safety of users. At RUNTIAN, we adhere to industry safety standards, making certain that each railing system is reliable and stable. Our commitment to safety underscores our dedication to creating products that inspire confidence and trust.

Customization and Flexibility:

Assembling allows for customization and flexibility, enabling us to create railing systems tailored to the unique needs of our customers. At RUNTIAN, we understand that every project has distinct requirements, and we approach each assembling process with versatility and adaptability.

Assembling is the pinnacle of the stainless steel railing production process at FOSHAN RUNTIAN NEW MATERIAL TECHNOLOGY CO., LTD. Through skilled craftsmanship, precision engineering, and attention to detail, we create railing systems that stand as a testament to elegance and resilience.

Our commitment to assembling goes beyond aesthetics and extends to the structural integrity and safety of every railing system. At RUNTIAN, we believe that a meticulously assembled railing system is not only visually appealing but also a symbol of reliability and strength.

When you choose RUNTIAN, you are choosing railing systems that are crafted with precision, durability, and care. Our dedication to the art of assembling ensures that each railing system is a masterpiece that elevates spaces with elegance and confidence. With each project, we strive to exceed expectations, delivering railing systems that are both functional and a source of timeless beauty.